PLC for beginners

Programmable Logic Controller (PLC) for Beginners

In our daily lives, we encounter the term "control" in various contexts. In recent years, with advancements in technology and the automation of processes, a specific technology has significantly contributed to the progress and automation of numerous processes in people's daily lives, especially in the industrial world.

This particular technology was initially used in the automotive industry but gradually expanded into other industries, such as drinking water, food processing, steel, and any industry that requires control and monitoring of its respective processes. We will explore how the PLC came into existence and the various ways it is used in the following sections.

What does PLC mean?

PLC has been extracted from the PROGRAMMABLE LOGIC CONTROLLER which is known as a special computer that is a programmable controller onto which various and diverse control programs can be written.

History of PLC invention

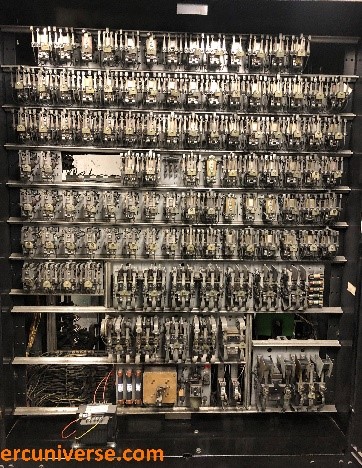

Before PLC was invented the control system in industries were made of relays and sometimes in some terms the number of relays were increased too much high then a bank of relays would have been appeared. The relays were used to turn on/off output equipment. This type of controlling had two critical problems:

- The function of relays was mechanical and excessive switching caused degradation, leading to relay failure.

- Relays use a lot of electricity, make lots of heat and soot, and take up lots of space.

- If a relay failed, the time required to locate it and repair the relevant process was very long and it caused the process to be out of operation for a considerable period.

These two critical problems made the specialists to find a solution. The first PLC was introduced and developed by General Motors (GM) in 1968.The automobile sector was the first industry to deploy PLCs into its operations. Their aim was to replace the hardwired relays and timers with programmable and flexible controllers.

Since then, PLCs have been broadly adopted as the standard automation control system in discrete manufacturing industries.

55-year-old relay board

How does PLC work?

As the name suggests Programmable Logic Controller is simply a special computer that is programmed that control and monitor certain processes programmatically and based on multiple data points. PLC cannot itself make any decision, Rather, it should be set up and programmed by relevant specialists using the manufacturers’ PLC programming software installed on the programming device. Then the created PLC program will be transferred directly to the memory of CPU (as one the most important hardware of a PLC device) over an Ethernet or Serial-based communication protocol.

Hardware components of PLC

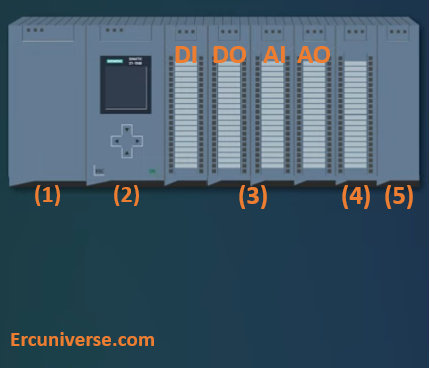

As we mentioned earlier PLC is a special computer. A computer has its own equipment such as keyboard, mouse, case, etc. Also a PLC unit includes of 5 main hardware modules like:

1. Power Supply

The most common input voltages of Power supply are 120/230 VAC (Volt-AC). Power supply regulates and converts the AC input voltages to DC (mostly 24 VDC). To power up all other PLC modules to work correctly, they do the wiring between the power supply and other individual PLC components.

In case of power supply, we need to consider two factors. First, the power supply we choose must provide the power needed for all PLC modules to keep the PLC system stable. And secondly, there is no data exchange between the power supply and other PLC components because the main job of the power supply is to provide the power needed by the PLC modules.

2. Central Processing Unit (CPU)

The second Module of Hardware of PLC is CPU which is the most important module among all PLC hardware components if the CPU stops working and not processing the program the whole system will shut down, that’s why we call it the brain of the PLC system.

The CPU controls and monitors all PLC system operations especially executing the PLC program based on status of input field devices so, it can decide what output field devices should do (In simpler terms, the process of flipping a light switch and the light turning on can be used as an example here).

3. Input and Output Modules (I/O)

In the example of a switch and a lamp, pressing the switch serves as the input, and the lamp turning on is accomplished through the output module. This operation, in more complex industrial processes, is used for tasks such as starting or stopping electric motors or any instrument with control logic, without the need for operator presence.

Based on the type of the signals is going to be used there two types of I/O modules: Digital I/O and analog I/O. Digital signals are used as on/off signals while Analog signals have a range of values.

4. Function Modules (FMs)

FMs are another part of PLC hardware use in motion control applications with high accuracy. Whenever the I/O signals consist of high-accuracy pulses the FMs are needed to handle high-speed counting.

An interesting point about the function modules is they work independent of the CPU. It means regardless of tracking and providing I/O signals, the FMs process the data as well which results in taking the load off the CPU and CPU can process and handle the remaining signals much faster.

5. Communication Modules

This Module supplies extra communication ports or protocols that an industrial system may need. Usually CPU contains communication ports such as Profinet with other field devices like HMIs over an Ethernet Network.

Also CM can be used to transfer data between PLC and VFD since it has Profibus port on it. This port provides a cable connection to have exchanging Data between PLC and VFD.

These Hardware Components are not limited to any model or Brand of a PLC; they are common in all modular PLCs around the world.

PLC Components shown in a SIEMENS SIMATIC series

PLC Language Programming:

PLC programming languages are specialized languages used to generate control logic for industrial automated equipment and processes. They all belong to either of two classes: graphical or textual. Graphical languages are structured with visual elements, whereas textual languages make use of strings of text.

The most common PLC programming languages are defined by the IEC 61131-3 standard, which includes:

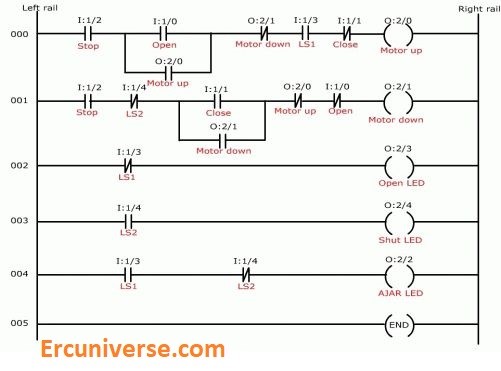

1. Ladder Diagram (LD):

Resembles electrical relay diagrams, with rails and rungs for logic representation—very user-friendly for electricians and technicians.

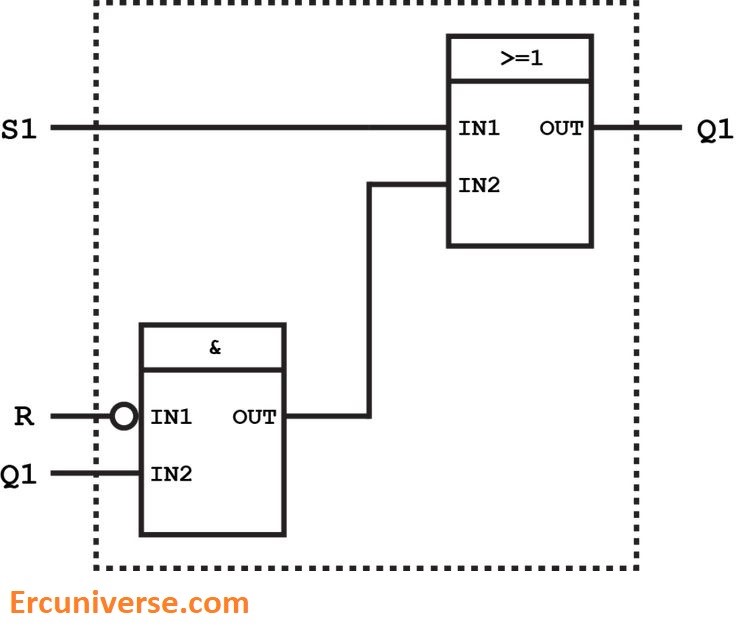

2. Function Block Diagram (FBD):

Uses graphical blocks to represent functions and their connections, making complex processes easier to visualize.

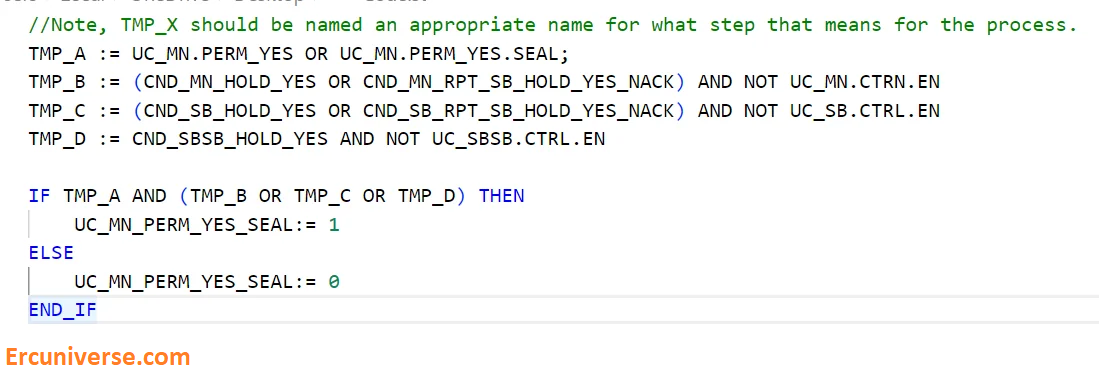

3. Structured Text (ST):

A high-level textual language similar to Pascal or C, suitable for complex calculations and algorithms.

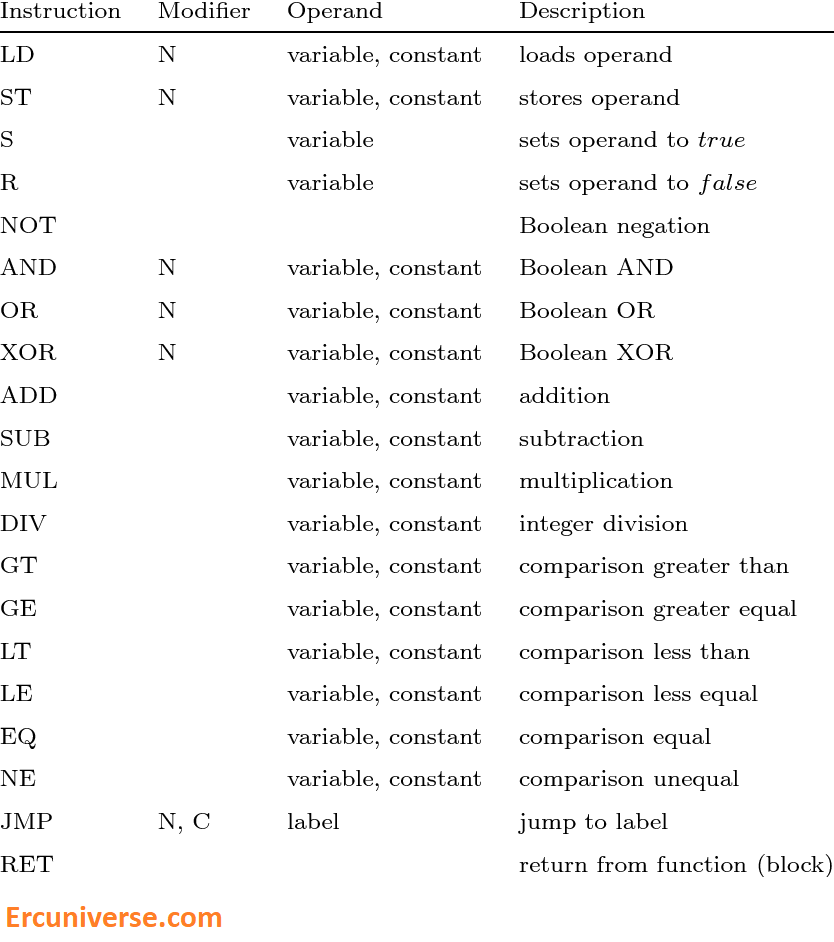

4. Instruction List (IL):

A low-level, assembly-like language (less common now, since IEC 61131-3 mostly emphasizes the others). IL commands has shown as below Figure:

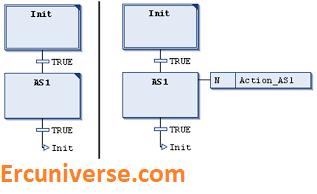

5. Sequential Function Charts (SFC):

Graphical language for designing sequential control processes, like step-by-step operations.

Different PLC brands may support subsets or variations of these languages, but these five are the core standards.

Which Company has the best PLC?

Some of the most famous companies producing PLC (Programmable Logic Controller) devices include:

1. Siemens

Popular Series: SIMATIC S7

Programming Languages: Uses TIA Portal software with languages like:

Ladder Logic (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Instruction List (IL) (deprecated in newer standards)

Sequential Function Charts (SFC)

Advantages:

Siemens PLCs are known for their robustness, extensive automation features, and seamless integration into industrial ecosystems. The TIA Portal provides a unified environment for hardware and software, facilitating easier configuration and programming. They are highly scalable, suitable for everything from small machines to large plants, and offer excellent communication protocols like Profinet and Profibus. Siemens PLCs also excel in diagnostics, reliability, and support for complex control strategies.

2. Rockwell Automation (Allen-Bradley)

Popular Series: ControlLogix, CompactLogix

Programming Languages: Uses RSLogix/Studio 5000 with:

Ladder Logic (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Advantages:

llen-Bradley PLCs are praised for their user-friendly programming environment (Studio 5000) and intuitive hardware design. They offer high flexibility, fast I/O processing, and seamless integration with other Rockwell products. Their systems support advanced networking, making them ideal for complex, distributed control systems. The brand is well-regarded for excellent technical support, reliability, and real-time performance, especially in North America.

3. Schneider Electric

Popular Series: Modicon M221, M340, or EcoStruxure Logic

Programming Languages: Uses EcoStruxure Machine Expert (formerly SoMachine) with:

Ladder Diagram (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Advantages:

Schneider's PLCs benefit from easy-to-use software (EcoStruxure Machine Expert), facilitating rapid development and deployment. They are known for their adaptability, supporting a broad range of applications from simple machines to complex manufacturing lines. Schneider emphasizes energy efficiency, open protocol support (like Modbus, Ethernet/IP), and reliable operation in diverse industrial environments.

4. Omron

Popular Series: Sysmac NJ/NX series

Programming Languages: Uses CX-One software with:

Ladder Diagram (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Advantages:

Omron PLCs are valued for their simplicity, compact size, and quick setup. They excel in automation for manufacturing and packaging, with integrated motion control capabilities. Omron’s focus on innovation includes advanced sensing and robotics support, making their solutions ideal in flexible automation environments. Their devices are generally cost-effective and easy to maintain.

FAQs:

What does PLC mean?

PLC stands for programmable Logic controller. PLC is a computer that controls and monitors all devices in a process.

Who invented the PLC?

Firstly, the PLCs were invented and developed by General Motors company (GMC) and in automobile industry to be replaced by the cabinets of relays.

IS PLC a computer?

Yes, we can count PLC as a special Computer which is going to be used in control systems and with its own logics.

Which component of PLC can work independent?

Function modules can work separately and even when the CPU is not working.

Why motion controls can’t be connecting to standard I/O modules instead of FMs?

In these types of application (motion controls) the speed and accuracy are a must. Communication Module which has a profibus port can connect and exchange data between PLC and VFD by using profibus Cable.

What is the standard of PLC?

IEC 61131-3 has been named as the reference and standard of PLC devices and its programming logics.

What are the PLC programming Languages?

There are 5 programming languages as per as IEC 61131-3 standard. Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), Sequential Function Charts (SFC).